Uniflow Discharge Station

A Proven Innovation in Bag-in-Box Discharge Technology

Helping customers cut costs, mitigate risks, and increase profits through an innovative system that removes the difficulties associated with discharging thicker, or more... Read more

TPS-ACC-DISCHARGE

A Proven Innovation in Bag-in-Box Discharge Technology

Helping customers cut costs, mitigate risks, and increase profits through an innovative system that removes the difficulties associated with discharging thicker, or more viscous liquids.

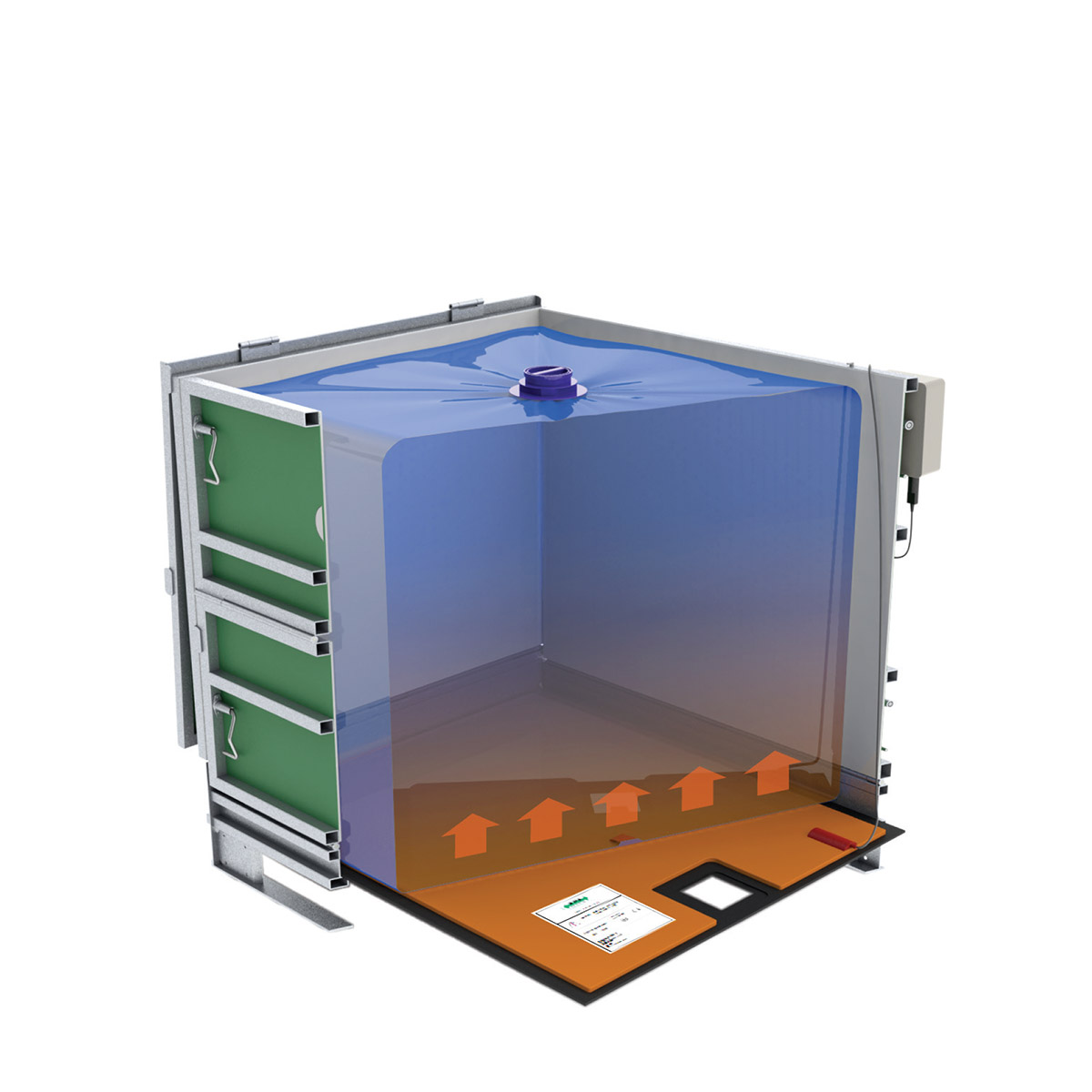

The TPS discharge station helps you maintain a perfectly consistent, measured flow when discharging. To see it action, watch the short video below where you can see the discharging of a 1000 litre IBC container.

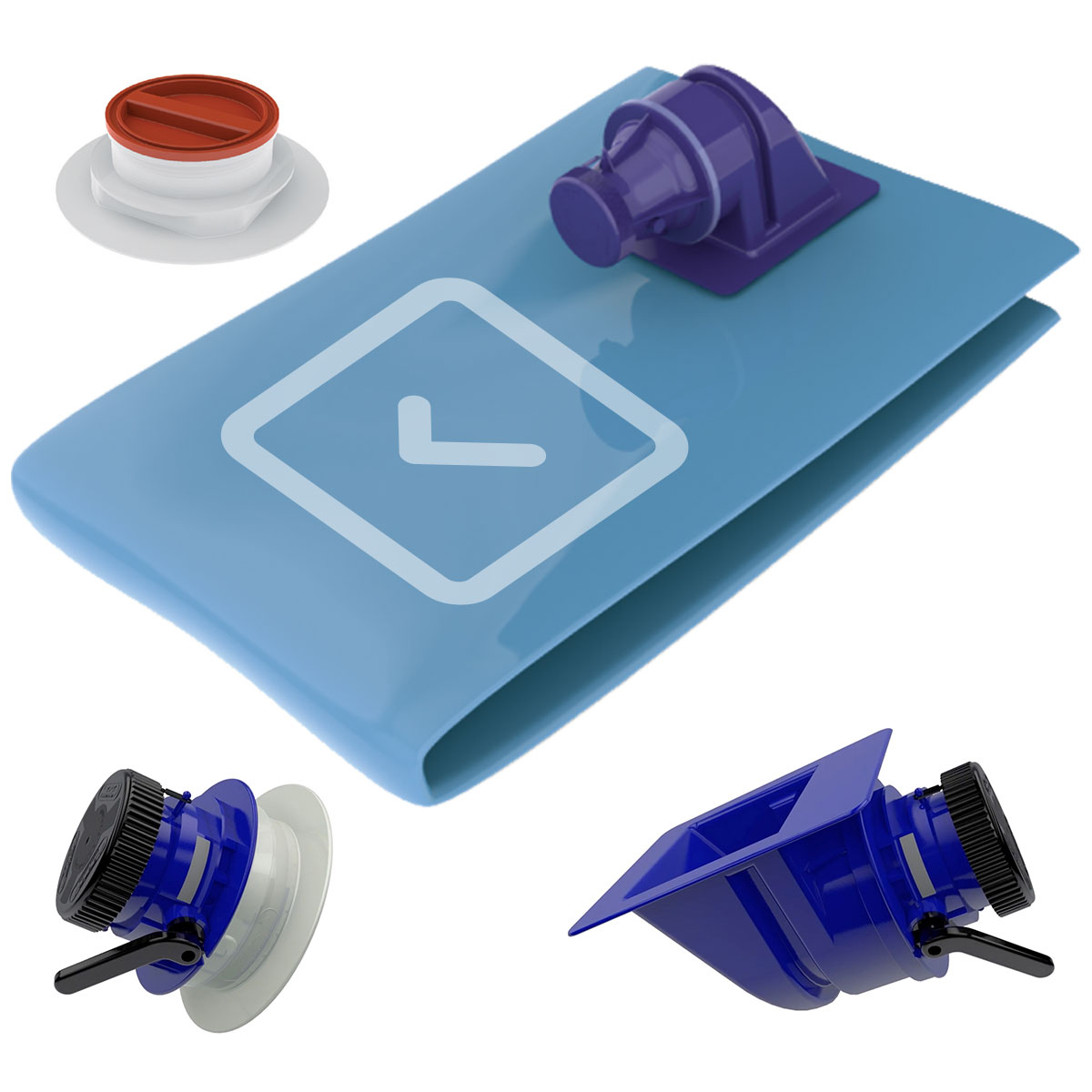

This is a proven system and easy for just one operator to manage. All the parts that touch the liner are designed to smoothly discharge the contents and protect the integrity of the product.

The data you will gain from using this system will demonstrate these advantages:

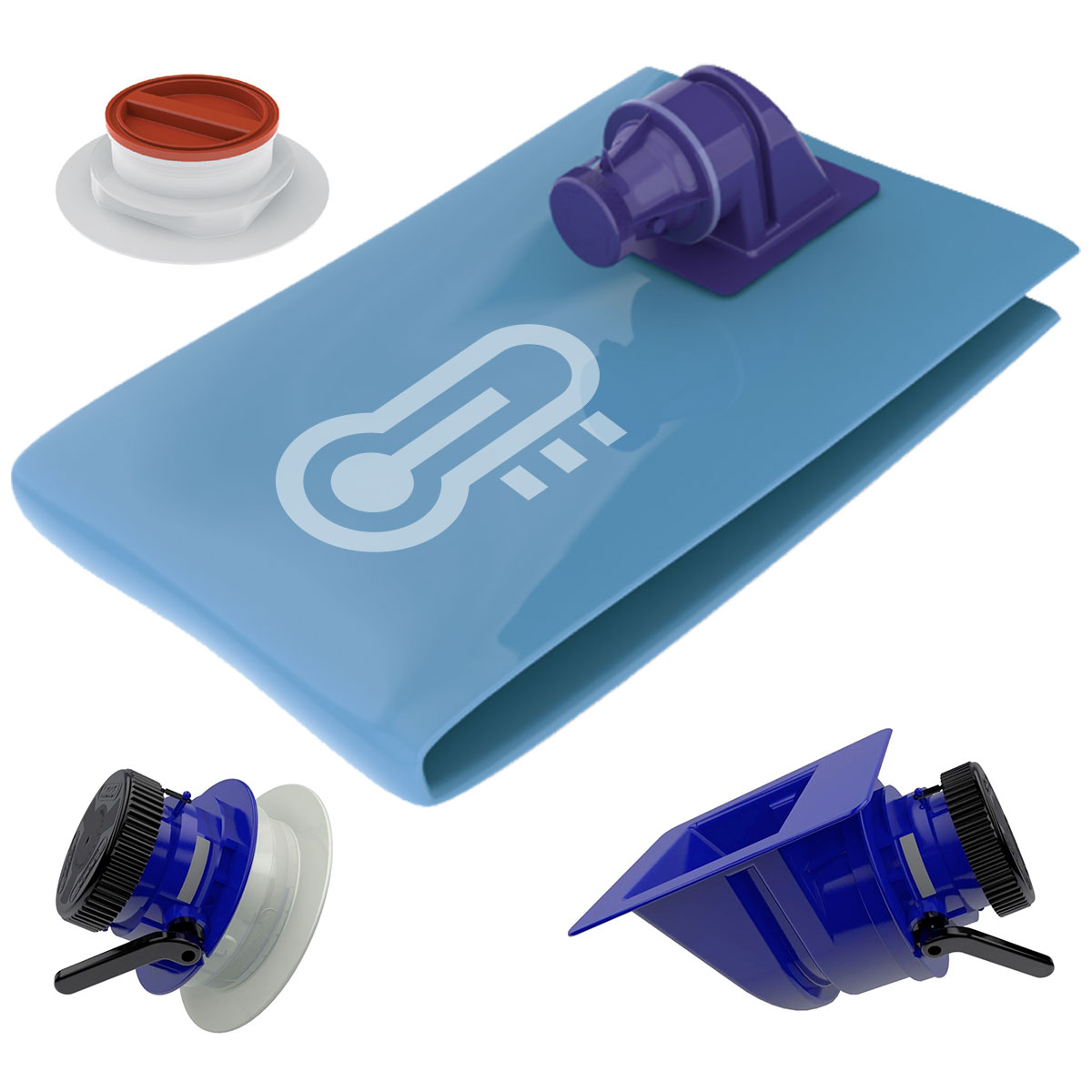

- Increasing product yield (and potentially quality) when discharging

- Reducing product loss in residue waste, cleaning or disposal costs

- Safety benefits for the operator, liquid contents and your business

- Combining product specific liquid liner bags and IBC containers

- Designed for discharging 1000 litre IBC containers

- An automated way of improving performance

Considering safety, there is no need for the operator to lean into the container or touch the liner when discharging because the process is fully automated. When the cycle is complete the operator can simply remove the liner and reuse or return the container.